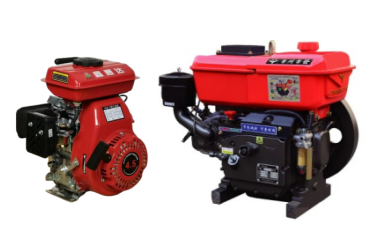

In the field of agricultural machinery, the engine serves as the core power source, and its type and performance directly affect the operating efficiency and application scope of agricultural equipment. Currently, the mainstream agricultural machinery engines on the market are mainly divided into two categories: gasoline engines and diesel engines. This article will conduct an in-depth analysis of the differences between gasoline and diesel engines from multiple dimensions, including working principles, performance characteristics, operating costs, and environmental friendliness, to help users better select and use them.

Working Principle – The Fundamental Distinction

Gasoline and diesel engines differ essentially in their working principles.

A gasoline engine adopts a spark-ignition mode: it uses a spark plug to ignite the air-fuel mixture, generating explosive force to push the piston and drive the engine. This process relies on precise timing of the spark plug to ensure efficient combustion of the mixture.

In contrast, a diesel engine uses a compression-ignition mode: the piston compresses the air in the cylinder to an extremely high pressure, which rapidly raises the air temperature to the self-ignition point of diesel fuel. At this moment, diesel is injected into the cylinder and immediately ignites, producing power. This difference in ignition methods lays the foundation for their distinct performance traits in agricultural applications.

Performance Characteristics – Which Suits Agricultural Needs Better?

Power Performance – Torque and Efficiency for Farm Work

Diesel engines, due to their compression-ignition design, have a much higher compression ratio (typically 16:1 to 22:1) compared to gasoline engines (usually 8:1 to 12:1). This higher compression ratio translates to greater thermal efficiency (diesel engines often reach 35%-45%, while gasoline engines are around 25%-30%) and stronger power output.

In practical agricultural scenarios—such as plowing with large tractors or hauling heavy loads—diesel engines excel, especially at low speeds. For example, a 4.5L diesel engine in a tractor can deliver a maximum torque of 500-600 N·m at 1500-2000 rpm, providing steady power for prolonged heavy-duty operations. Gasoline engines, while lighter, generally produce lower torque at low speeds, making them more suitable for light tasks like small-scale weeding or irrigation.

Economic Performance – Fuel Consumption for Long-Hour Operations

Fuel efficiency is a critical factor for agricultural machinery, which often operates continuously for 8-12 hours daily. Diesel engines have a significant advantage here: their fuel consumption rate is 20%-30% lower than that of gasoline engines under the same power output.

Take a medium-sized tractor as an example: a diesel-powered model consumes approximately 2.5-3.5 liters of fuel per hour during plowing, while a gasoline-powered counterpart of similar power consumes 3.8-5 liters per hour. Over a typical 100-day farming season, the diesel tractor can save 130-150 liters of fuel—equivalent to a cost reduction of $50-$80 (based on average fuel prices), a substantial saving for farmers.

Durability & Reliability – Withstanding Harsh Farm Environments

Agricultural work environments are often harsh: dusty fields, muddy roads, and large temperature fluctuations all test engine durability. Diesel engines have a simpler structure (no spark plugs or ignition coils) and more robust components (thicker cylinder walls, stronger crankshafts), enabling them to operate stably in harsh conditions for 8,000-12,000 hours before major overhauls.

Gasoline engines, by contrast, are more sensitive to dust and moisture. Dust can easily clog their air filters, leading to poor combustion, while moisture may damage ignition systems. Their average service life before overhauls is usually 5,000-7,000 hours, requiring more frequent maintenance to adapt to farm environments.

Operating Costs – A Long-Term View for Farmers

Operating costs of agricultural machinery engines extend beyond fuel consumption, encompassing maintenance, parts replacement, and downtime losses.

Maintenance & Repair Costs

Diesel engines have lower maintenance demands: their oil change intervals are longer (every 250-300 hours, compared to 150-200 hours for gasoline engines), and they require no replacement of spark plugs or ignition coils. Annual maintenance costs for a diesel engine in a tractor are typically $150-$250, while gasoline engines cost $200-$350.

When parts replacement is needed, diesel engine components (e.g., pistons, bearings) are more durable and less frequently replaced. A diesel engine’s major overhaul costs $1,500-$2,500, while a gasoline engine’s overhaul may cost $1,200-$2,000—but since gasoline engines need overhauls more often, their long-term repair costs are actually higher.

Downtime Costs – Avoiding Delays During Critical Farming Periods

Downtime during peak farming seasons (e.g., planting, harvesting) can lead to significant losses for farmers. Diesel engines’ higher reliability means they have 30%-50% fewer breakdowns than gasoline engines. For example, a diesel tractor may experience 1-2 minor breakdowns per year, while a gasoline tractor may have 3-4. Each breakdown can cause 1-2 days of downtime, resulting in lost income of $300-$500 per day—costs that far exceed routine maintenance expenses.

Environmental Friendliness – Meeting Modern Emission Standards

With the tightening of global environmental regulations (e.g., the EU’s Stage V standards, China’s National IV standards), both gasoline and diesel engines for agricultural machinery have made significant advances in emissions control.

Modern diesel engines use technologies like common rail fuel injection, exhaust gas recirculation (EGR), and diesel particulate filters (DPF) to reduce particulate matter (PM) and nitrogen oxide (NOₓ) emissions. Gasoline engines, meanwhile, adopt electronic fuel injection (EFI) and catalytic converters to lower hydrocarbon (HC) and carbon monoxide (CO) emissions.

Currently, mainstream agricultural engines of both types meet regional emission standards. Farmers should choose based on local policies: for example, regions with strict PM limits may prefer gasoline engines, while areas focusing on NOₓ reduction may opt for advanced diesel engines with SCR (Selective Catalytic Reduction) systems.

Conclusion & Recommendations – Choosing the Right Engine for Your Needs

Gasoline and diesel engines each have unique advantages for agricultural machinery, and the choice depends on your specific needs:

-

Choose a gasoline engine if: You use small agricultural equipment (e.g., walk-behind tillers, small sprayers), operate for short periods (less than 4 hours daily), or work in regions with strict PM emission regulations. Its light weight and easy startup make it ideal for light, intermittent tasks.

-

Choose a diesel engine if: You own large machinery (e.g., tractors, combine harvesters), need continuous operation (8+ hours daily), or prioritize long-term fuel savings and durability. It is the best choice for heavy-duty, high-intensity agricultural work.

As new energy technologies (e.g., hybrid systems, hydrogen engines) develop, future agricultural engines will become more efficient and eco-friendly. However, for now, gasoline and diesel engines remain the most reliable and cost-effective options for most farmers.